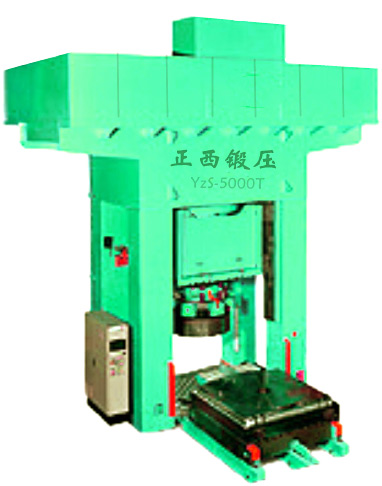

Kub Forging HYDRAULIC XOVXWM

YZ14 Sai Dawb Forging Hydraulic Xovxwm

Ncej hom thiab plaub-kem qauv;

Siv Servo tswj system, muaj zog txuag;

Ceev 400 ~ 1000mm / s, tsim 50 ~ 200mm / s;

Lub cev yog welded nrog q355b cov khoom siv, nrog muaj zog tag nrho rigidity;

Nruab nrog cov ntsia liaj qhov rooj sab sauv thiab ob npaug kev tiv thaiv kev nyab xeeb ntaus ntawv;

Yeem tsotxiliaation chaw ntaus ntawv, ib pawg xuas nrig ntaus punching ntaus ntawv, precision automering forging, tswjfulator thiab lwm yam kev teeb tsa;

Pub dawb zam, haum rau cov loj sau cia nrog cov tsos yooj yim, rau kev zam ntau ntau cov ntses loj, cov khoom qab zib, kev noj qab haus huv thiab cov hlau;

Haum rau Forging ntawm ntau cov hlau, txheej hlau, cov kabmob hlau, cov kabmob hlau, lub caij nplooj ntoo hlau, hlau loj alloy;

Siv nyob rau hauv Aerospace, hwj chim, kev lag luam, nkoj nkoj, tsheb thauj mus los thiab lwm daim teb;

Precision Tuag Forging Hydraulic Xovxwm

Ncej hom thiab plaub-kem qauv, uas tuaj yeem siv rau kub forging lossis txias txias.

Servo tswj system, micro-txav molding, siab thiab txoj hauj lwm tswj tau 1%;

Kho tau nrawm 1 ~ 100 hli / s, stepless ceev hloov, muaj kev sib tw siab;

Lub cev yog welded nrog q355b cov khoom siv, nrog muaj zog tag nrho rigidity;

Nruab nrog sab sauv thiab qis dua cov thooj voos kheej kheej, ejection lub tog raj kheej muaj lub zog ua kom haum rau kev tswj kev xaiv Ejection;

Dav siv hauv tsheb, tshuab, Petrochemical, Boiler Raug, Aerospace, nkoj tsis muaj kev lag luam thiab lwm yam lag luam.

Lub sijhawm ib-lub sijhawm ntawm polyhedral cov qauv muaj peev xwm ua kom muaj lub zog ntau lawm, txo cov nqi ntau lawm, thiab txhawb qhov sib zog.

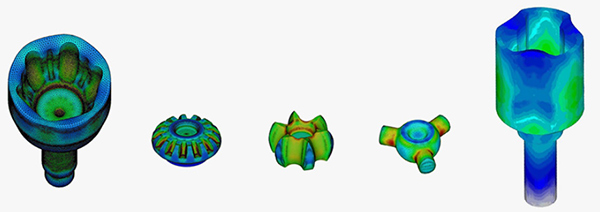

Kub tuag Forging Hydraulic Xovxwm

Lub ntsiab tseem ceeb ntawm kev tuag kub tuag yog kev tswj hwm ntawm qhov kub sib txawv ntawm pwm thiab tsim feem. Cov pwm kub tuaj yeem tsim kom siab dua cov khoom kub, thiab tsis forging cov txheej txheem zoo li qub thiab equatiaxed zoo siv lead ua morphology;

Siab tswj qhov tseeb ± 0.1mpa, txoj hauj lwm tswj tau ± 0.02mm.

Txoj kev ua nrawm nrawm nrawm, cov khoom tsim muaj cov khoom siab siab thiab tus nqi qis ..

Yeem hluav taws xob cua sov, feem ntau zaus thiab lwm cov hau kev cua sov, kev thauj khoom siv cua sov, txav tawm ntawm kev ua haujlwm;

Dav siv nyob rau hauv kev thauj mus los, tsheb, aerospace, nkoj nkoj, vaj tse, 3c electronics thiab lwm yam teb

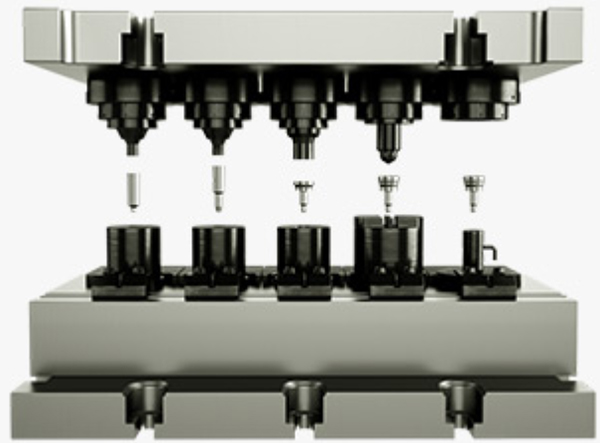

Ntau Sequence Tuag Forging Hydraulic Xovxwm

Ntau sib luag tuag fuling hydraulic xovxwm yog ntau-chaw nres tsheb synching khoom, thiab tseem siv tau kev sib sau ua ke thiab cov txheej txheem txias dua;

Servo tswj system, ruaj khov tswj, muaj zog txuag;

Cov Qauv Fuselage Qhia qauv qauv, nrawm forging 2 ~ 5 ua, 3 ~ 30s / sijhawm zam txim ceev, siab forging yog;

Q355b Khoom Siv Welded lub cev, muaj zog zuag qhia tag nrho;

Mekas li 1 ~ 80mn, yeem siv tsis siv neeg chaw tso khoom siv, tsis siv neeg thauj khoom thiab thauj khoom siv stompress thiab lwm yam kev teeb tsa.

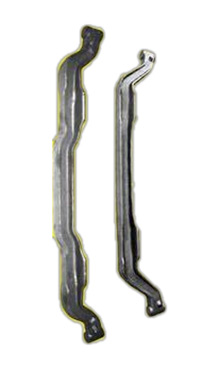

Muaj feem xyuam rau ntau yam forging cov khoom lag luam nrog cov duab yooj yim thiab cov duab sib xws;

Cov ncej me me, ntiv nplhaib, ncuav mog qab zib, ingot, phaj, tes tsho, ua cov kabmob;

Forging ntawm ntau cov hlau, txheej hlau, cov kab hlau, cov kabmob hlau, cov hlau, lub caij nplooj ntoo hlav thiab kub alloy.

Ntau qhov kev coj ua tuag forging hydraulic xovxwm

Cov txuj ci ntawm hydraulic no yog tsim nrog cov qauv roj roj loj thiab tom ntej, sab laug, thiab sab ruaj khov thiab lub zog ruaj khov;

Cov qauv yooj yim, cov khoom siv siv tau siab yog siab, cov nqi tsis quav ntsej tau tsim ib zaug, thiab tus nqi tsim yog kev txo qis;

Kev ceev 50 ~ 400mm / s, synchronous extrusion nrog sab lub tog raj kheej; lub cev yog welded nrog q355b cov khoom, nrog muaj zog tag nrho rigidity;

Cov khoom lag luam tseem ceeb muaj cov ntsiab lus siab thiab tsis muaj forging tuag taper; siv Servo tswj system, muaj zog txuag;

Siv rau ntau cov khoom siv nrog cov duab nyuaj thiab cov khoom loj;

Haum rau ntau lub cev valve, pob qij txha, xaus pob qij txha, cov ncej disc cov pob los ua ke thiab lwm yam kev lom zem;

Haum rau Forging ntawm ntau cov roj carbon, tooj liab, txhuas thiab aluminoy steel cov ntaub ntawv;

Nws tuaj yeem raug teeb tsa ncaj qha nrog kub xuas nrig xuas nrig ntaus pob thiab theem nrab zaus ua kom muaj zog kom paub tau cov pwm ntxiv;